By V. Jegatheesan

Tanjung Tualang Dredge No. 5. Image credit: V. Jegatheesan.

The Tanjung Tualang tin dredge, also popularly referred to as TT5, is an old dredge that went out of use as the tin industry faded away in the 1980s, with tin giving way mainly to aluminium. Nostalgia and a keen interest in preserving this machinery, led to its refurbishment, so as to give the populace a chance to see how it worked and how it helped the tin mining industry. It is now located on the 9th Km, Jln Tanjung Tualang, 31000 Batu Gajah.

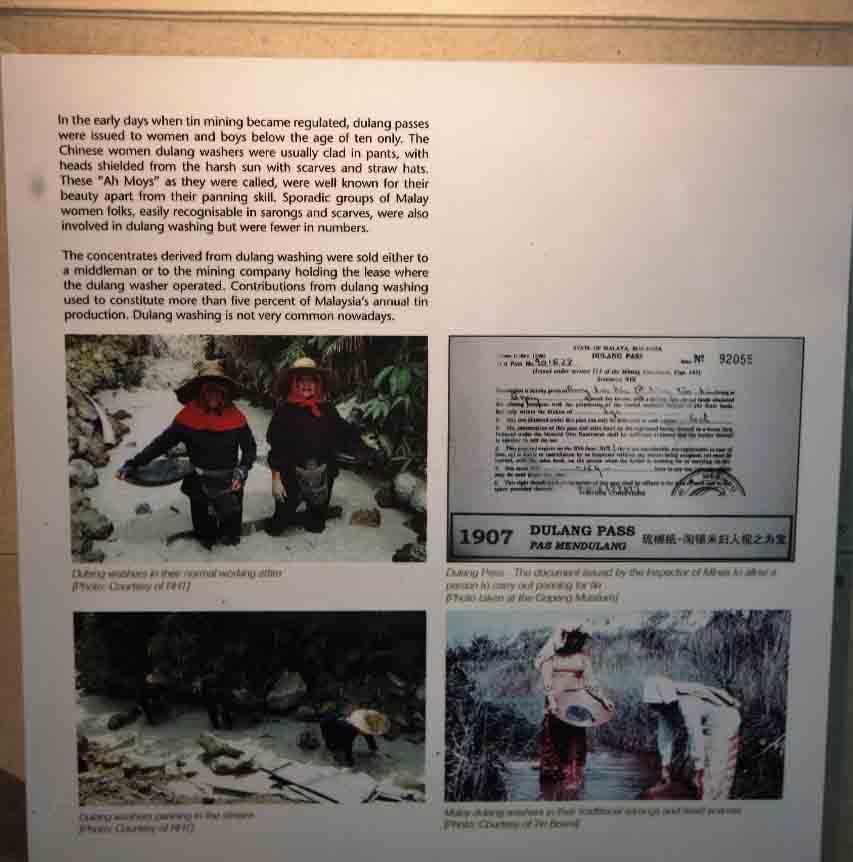

Tin has been a lucrative product in Malaya for a long time. The Dutch of the 18th century were well known to have negotiated agreements for tin supplies from the areas around Pulau Pangkor and Kuala Selangor. However, mining methods, such as panning, were very basic. A large tray or dulang, was used to scoop water and sand in the rivers. The sand and earth would be filtered out and the heavy ore would remain. This would be further processed to make ingots and then sold, ending up ultimately as tin products. Tin has had many uses. Its main usage was in the canning industry, making bullets and, nowadays, in the electronic industry in solder. Interestingly, while many think a tin can is all tin, it is actually a tinned can – a steel can, which gives it strength, plated with tin, which prevents corrosion!

Dulang washing was of course an arduous process and not very productive. Subsequently, better technology emerged including opencast tin mining in which pumps shoot water at high pressure onto the sloping ground. The loosened earth or slurry is conveyed to the top of a sluice – palong – andwater pushes it down trellises; the heavier ore is held back by wooden slats while the rest of the earth and sand flows into a large lake. The recovered ore is then sent to a smelter for further processing and export. This was still labour-intensive. These methods were used until the end of the large-scale tin-producing era. Dulang washing is back in practice with the current rise in demand for tin.

Image credit: A poster in the TT5 Visitor Centre

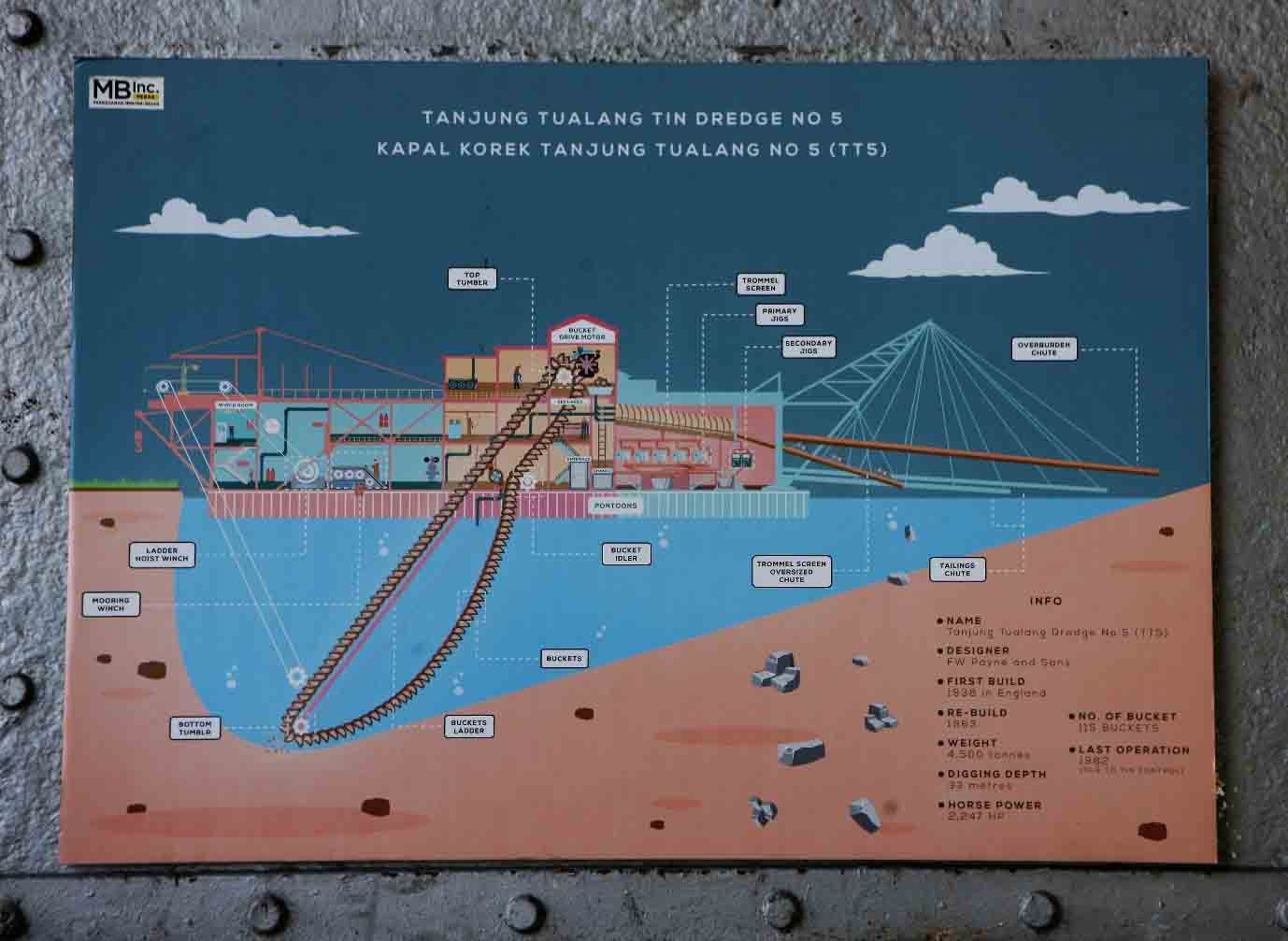

The dredge evolved from a simple ‘spoon dredge’ in 1862 through to the bucket dredge of the 1880s used in New Zealand and Australia. Since 1891, attempts were made to construct a dredge in Kinta, but all failed. In January 1913, Malayan Tin Dredging Ltd. initiated the first operational dredge in Batu Gajah; it later owned six of them. These were steam-operated. The TT5 is one of the five owned by its sister company, Southern Malayan Tin Dredging Ltd. It was built in 1938 by F. W. Payne and Company. Upgraded and electrified in 1963, it ceased operations in August 1982. In 1997, the Malaysian Mining Corporation (MMC), which subsequently owned the dredge, donated TT5 to the Perak State Government, which, since 2017, has spent almost Rm 10 million on its repair and maintenance.

A dredge in those days typically cost Rm 40 million to build. At today’s prices, a dredge would cost Rm 200 million. This behemoth could scrap up tin-bearing earth, 24/7, as is said nowadays. In very large quantities too. However, the cost was prohibitive so only companies with the ability to lay out large capital could afford the dredge. These were usually European companies, mainly British. This is why, other tin-mining methods continued. In due course, 123 dredges produced 60% of the tin, while other methods produced the remaining 40%. In 1912 some 80 per cent of Malaya’s tin production was under Chinese management, by 1931 British firms accounted for more than 60 per cent of total tin production.

Those who travelled along the Penang Singapore trunk road would remember seeing these dredges. But we all drove past assuming they would always be there. But not so. Over the years, greater use of aluminium, falling tin prices as well as increased production in Indonesia and China adversely affected the production in Malaysia. It was simply not economically viable.

TT5 is now restored to showcase how these mighty machines worked to contribute to the economy of Malaysia. Its actual operation area was not far off from where it is now located. A guided tour is provided and takes about 30 minutes. In fact this article transcribes the tour by Volunteer Guide, Encik Hafizal Arif. Note that this article describes TT5 only as other dredges will differ in size and equipment.

The process in its elements is very simple. Large quantities of tin-bearing earth were continuously scrapped from the ground by a conveyor made up of large metal buckets, processed mechanically to separate the tin from the earth, collect the tin and discharge the rest back into the lake on which it floats. A more detailed description, avoiding technicalities, is transcribed from the guided tour.

The dredge weighs 4500 tons and is 75m in length, 19.5m in width and four floors in height. A NO ADMITANCE signage at the entrance is in English, Chinese, Punjabi, Jawi and Tamil, reflecting the various groups of people working on this dredge.

Signage reflecting the various groups working on the dredge.

Image credit: V. Jegatheesan.

The entire structure floats on 47 pontoons. These are hollow tanks which keep the dredge afloat in the water. In this dredge, the pontoons are 3.1m deep and are accessible for maintenance, mainly patching leaks.

Pontoon top with the cover off. Image credit: Maganjeet Kaur.

TT5 has 115 buckets. These two-ton buckets are set on a looping chain, or ladder, in the front of the dredge. The ladder continuously circulates and can be lowered for the buckets to scrape the lake bed or the earth face on the lakesides beneath the water. Being a moderately-sized dredge, TT5 can scrape down to 33m. Other dredges can go down to even 100m.

Buckets on the looping chain. Image credit: V. Jegatheesan.

As the now three-ton buckets move up the ladder, they carry the scooped earth to the top of the dredge into trommel screens. These screens are cylindrical and perforated.

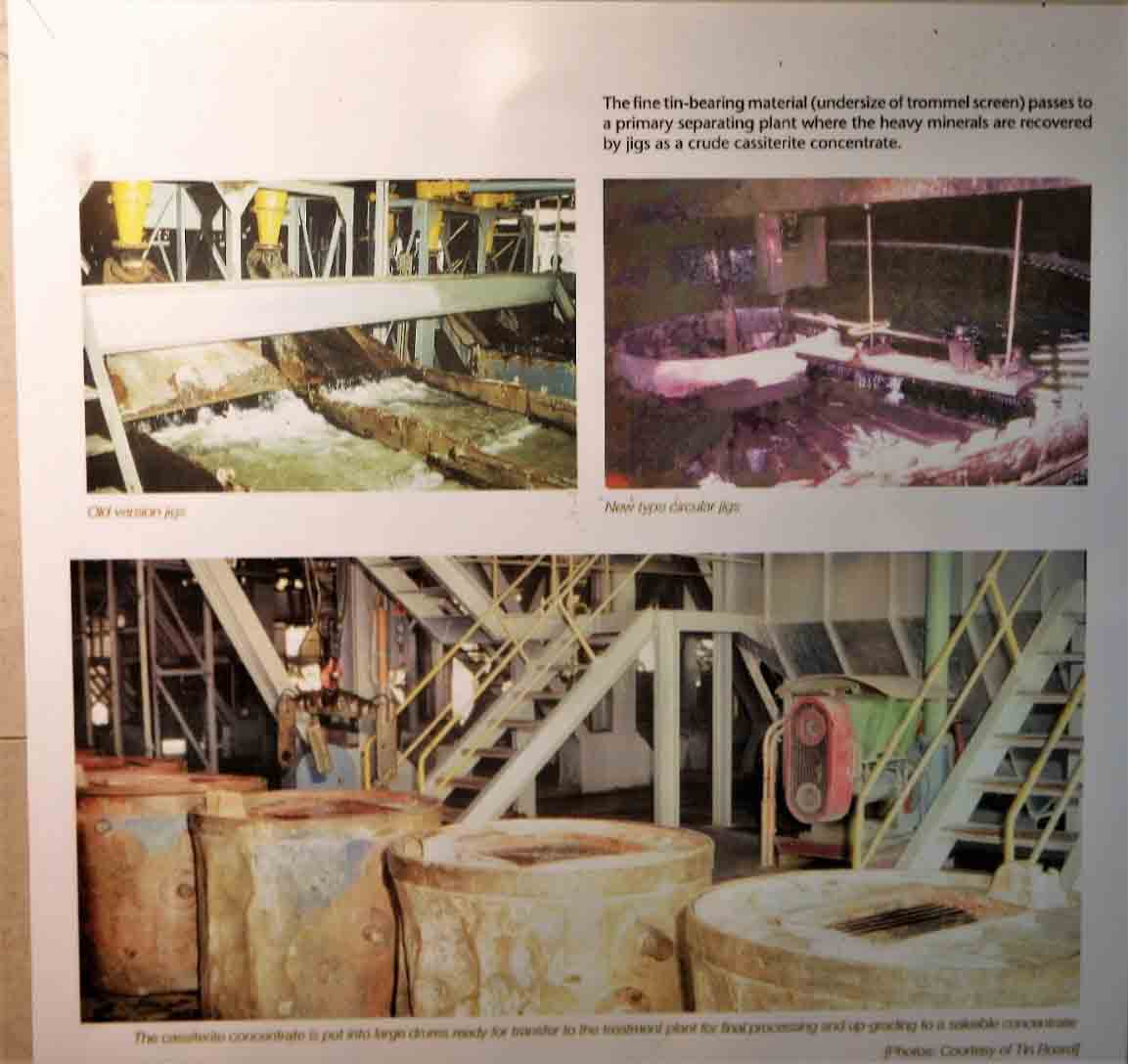

Jets of water wash through the earth in the trommel screen to separate the heavier tin ore. The ore is passed into vibrating jigs to further filter the ore. The jig is equipped with a screen or sieve that allows smaller particles to pass through while retaining the larger, denser particles. After a second jig, the purer ore (Cassiterite Concentrate) is channelled to be stored in tanks. We were restricted from visiting this area. The water used in the screen and jigs is pumped up from the lake itself. The sand and unwanted material after these processes, called tailings, are discharged through the chutes out at the back of the dredge into the lake.

The tank can hold one ton and one day’s dredging produced 30 tons. A crane on either side will carry the tanks out to the lakeside. It is later sent to the smelting plant in Penang. The resulting ingots are then exported.

A rough estimate values a day’s production at 30,000 to 35,000 USD of the time. It seems that a year’s production could recover the cost of the dredge! This is the reason that the tank area access is limited only to authorized personnel to prevent theft by stuffing ore into pockets or helmets. Even the discharge chutes for the tailings have a spider web netting to prevent anyone from climbing in.

Hafizal Arif explaining the storage tank for the ore. Image credit: V. Jegatheesan

Spider netting encircling the discharge chutes. Image credit: V. Jegatheesan.

A description of the dredging process. Image credit: Maganjeet Kaur

Poster in the Visitor Centre. Image credit The Tin Board.

The operation is managed by a Dredge master. Employees work in three shifts and do not live on board. They are ferried by a small boat. Each shift has 20 people. There is a pantry area for them to rest and have their meals, which are brought by them as there are no cooking facilities. There is a toilet at the back, over the lake.

Pantry at the top. Image credit: Maganjeet Kaur.

Though TT5 is tethered to the lakeside by ropes today, the dredge had cables in front and sides. The cables were attached to a mooring winch. The dredge could be moved by winching in or out.

Tethering of dredge to the side. Right image shows the gangway to the dredge. Image credit: V. Jegatheesan.

Views of either side of the dredge decks. Image credit: V. Jegatheesan.

Over the years, dredges have been sold to Thailand or Indonesia, while some have even been scrapped.In 2015, the Perak State Government mandated the Menteri Besar Incorporated (MB Inc.) to conserve the TT5. Visitors can go onto the dredge and its workings are explained by guides. Visits can be made by calling ahead and specifying a time slot or walking in to join the next group.

Board showing layout of the TT5 Park. Image credit: V. Jegatheesan.

Since 2018, TT5 has been part of the Kinta Valley National Geopark. The Visitors Centre and TT5 tours are managed by the Operation Executive, Encik Aizad Azeli.

To cap the extensive works to preserve the TT5, in March 2023, the Institution of Mechanical Engineers United Kingdom, presented Tanjung Tualang Tin Dredge No.5 an Engineering Heritage Award for being well-maintained, contributing to the state and national economy and having its own heritage characteristics. It is the first tin mining dredge to receive such an award.

Image credit: New Straits Times 2023, March 23

In 2023, TT5 received the Travellers Choice Award from Tripadvsor.

TT5 is well worth a visit.

References:

Last surviving tin dredge TT5 receives IMechE award from UK. (2023, March 23). The New Straits Times. https://www.nst.com.my/news/nation/2023/03/892188/last-surviving-tin-dredge-tt5-receives-imeche-award-uk#:~:text=BATU%20GAJAH%3A%20The%20iconic%20Tanjung,Engineers%20(IMechE)%20United%20Kingdom.

EARLY 20TH CENTURY TIN MINING DEVELOPMENT. In Economic Heritage Malaya. https://www.ehm.my/publications/articles/about-tin-mining#:~:text=EARLY%2020TH%20CENTURY%20TIN%20MINING,much%20of%20the%2020th%20century.

A gold mine in tin. (2007, August 30). In Malaysian Bar. https://www.malaysianbar.org.my/article/news/legal-and-general-news/general-news/a-gold-mine-in-tin

Tanjung Tualang Tin Dredge. (2023). httpstt5perak.com